A Rocktopus, a 3D-printed octopus with the head of actor and former wrestler Dwayne “The Rock” Johnson, sits on a table in Room 185 on Sept. 2. Students from the Engineering III class created and sold Rocktopi to raise money for two class robots to compete in the FIRST Tech Challenge events that will take place once a month from October to January. “It would provide more opportunities for students to have direct ownership of competition participation,” science department teacher and Robotics Club sponsor Dr. Gabe Wilfong said. “It’s kind of like too many cooks in the kitchen. Like, six people can’t make cookies – only two or three do the work. Same here. If I just had one robot team, then my 20 students would be able to build different vehicles, but ultimately, we would only send the best one to competition. Now we get to send the best two.” Photo by Anna Shaikun

Members of the CCHS Engineering III class are raising money for a robotics competition by selling Rocktopi.

It sounds like a monster in a horror movie – half octopus, half Dwayne “The Rock” Johnson. However, it’s only a few inches tall and made of plastic. Enter the Rocktopus.

Although the concept was originally invented soley for amusement, the Clarke Central High School Engineering III class started selling Rocktopi at the beginning of the school year.

“We were joking around and our teacher wasn’t here. Usually when he’s not (there), we try to find a stupid thing to do,” Engineering III student and Rocktopus co-creator Matthew Zavaleta, a junior, said. “We were messing with (designs involving) the Rock because we were listening to his song and his head is kind of funny. Then we saw a kid’s commercial (with) an octopus come up and I’m like, ‘What if we just put an octopus on the head of the Rock?’ And that’s where he was born.”

A timelapse shows a Rocktopus during the 3D printing process. Engineering III student Matthew Zavaleta was one of the primary designers of the Rocktopus, and used multiple design programs to complete it. “When it’s done printing, the 3D printer will lower it and the MakerBots (will) just slide it out. Then we’ll have to peel off the bottom part, which is called the raft. The raft is where it keeps it from sticking onto the (printer),” Zavaleta said. “And when you want to take it off, it breaks off. So the raft is like a protection thing, underneath that is support. It’s just temporary lines. And then after that you have a fully functional Rocktopus.” Video courtesy of Tyus Dekle

Engineering III student Tyus Dekle, a junior, organized Rocktopus production into Rocktopus, Incorporated, earning the position of Chief Operations Officer.

“I was just thinking, ‘Hey, people like buying stupid things.’ Look at the Pop-It. People love buying little fidgets and stuff. I was sitting there fidgeting with (a Rocktopus, thinking), ‘People would pay money for this,’” Dekle said. “We were all being hooligans, and just messing around, and I was like, ‘Everyone sit down, we need to have a board meeting.’”

The Rocktopus fundraiser will allow Robotics Club sponsor and science department teacher Dr. Gabe Wilfong to take two teams to the FIRST Tech Challenge for the first time, while also giving students an advantage in the marketing aspect of the competition.

“Each year for the competition, we have local dues to FIRST Robotics, which is like the governing body for the robotics competition. There’s also national dues that each team has to pay. It’s $295 per team. So this year will be the first year that we’ll have two teams competing,” Wilfong said. “In addition, one of the components of the robotics competition is to demonstrate marketing skills, data collection skills (and) leadership skills. So, this was perfect because it fit right into the curriculum.”

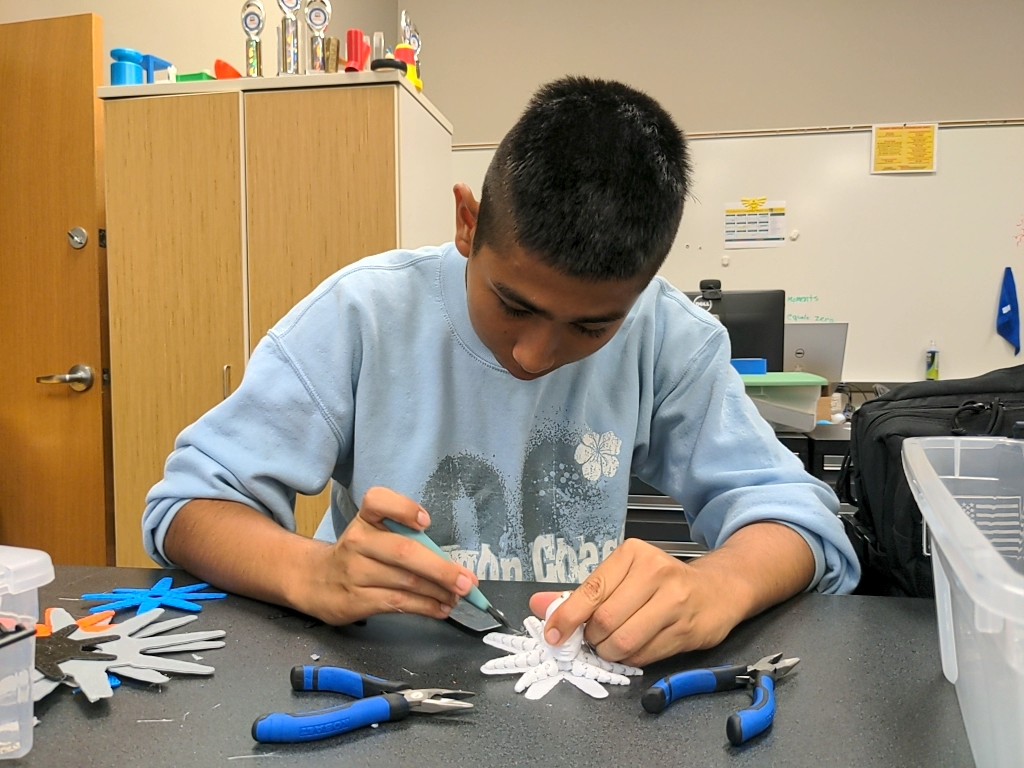

Engineering III student and Rocktopus, Incorporated co-founder Matthew Zavaleta, a junior, scrapes a Rocktopus tentacle off its base. Zavaleta used several design programs to create a functioning Rocktopus. “We had to use a software called OnShape to actually get a design and make the shapes of it. We had to use another software for visualizing the head and then we put those together with the octopus body (template) on OnShape,” Zavaleta said. “After that, we put in our computer, we put in a new software for the 3D printers to actually read it. Then when we’re ready to print it, we press a button where it actually shows you how they will actually print and it’ll give you an estimated time (of) how long it will be printing.” Photo by Anna Shaikun

The Rocktopus fundraiser is the first time the Engineering III class has marketed towards the CCHS student body, and has earned over $1,100 as of Oct. 12.

“(The Rocktopus project) has gone above and beyond my expectations. I imagined we’d sell like 20 or 30 and maybe make like $150 or something like that,” Wilfong said. “Any extra money allows us a lot of flexibility to buy items that we need.”

Dekle wants the Rocktopus project to continue even after the current Engineering III class concludes.

“We’re thinking along the lines of next semester, possibly passing it along to the next class, because we won’t be able to do it anymore,” Dekle said. “We’re hoping that people will continue buying them, because it is a great fundraiser and it’s really fun to do, especially for us.”